Saturday, September 16, 2006

Tech: The importance of aerodynamics

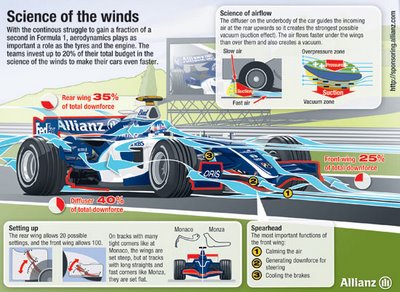

In the tough struggle for crucial seconds in Formula 1, aerodynamics play a fundamental role. The teams invest up to 20% of their total budget in the science of the winds, making their cars even faster with innovative aerodynamic designs. Meticulous precision work is undertaken down to the last millimetre, according to the motto: races are won in the wind tunnel and lost on the track.

A stroke of genius by Colin Chapman in 1972 showed the way ahead for Formula 1. The legendary designer and team boss equipped his Lotus 72 with a flat front end in the form of a closed wedge, and hid the bulky radiators in side panels. Thanks to these revolutionary aerodynamics, supported by a rear wing, Emerson Fittipaldi won the World Championship for Lotus.

The significance of aerodynamics can be seen primarily in the downforce. The search for greater downforce has become the driving factor behind entire Formula 1 teams. The shape of cars is grinded on the computer, in the wind tunnel and on the track, and the wings and wind deflectors are styled just as much as the diffuser on the rear underside of the car. The aim of this precision work is to channel the airflows perfectly and so generate as much downforce as possible, which presses the car down onto the road and permits shorter braking distances and higher cornering speeds. Experts estimate 80% of the car’s grip is generated by the downforce and only 20% by the tyres.

But downforce is not everything: the recipe for true success is to find the best compromise between the greatest possible downforce and the lowest possible air resistance. There is no ideal set-up to suit every racetrack, so the true art of the designers is to get closer to the ideal than their competitors for every race. This is not an easy task, with 20 different possible settings for a rear wing and 100 possible settings for a front wing.

A stroke of genius by Colin Chapman in 1972 showed the way ahead for Formula 1. The legendary designer and team boss equipped his Lotus 72 with a flat front end in the form of a closed wedge, and hid the bulky radiators in side panels. Thanks to these revolutionary aerodynamics, supported by a rear wing, Emerson Fittipaldi won the World Championship for Lotus.

The significance of aerodynamics can be seen primarily in the downforce. The search for greater downforce has become the driving factor behind entire Formula 1 teams. The shape of cars is grinded on the computer, in the wind tunnel and on the track, and the wings and wind deflectors are styled just as much as the diffuser on the rear underside of the car. The aim of this precision work is to channel the airflows perfectly and so generate as much downforce as possible, which presses the car down onto the road and permits shorter braking distances and higher cornering speeds. Experts estimate 80% of the car’s grip is generated by the downforce and only 20% by the tyres.

But downforce is not everything: the recipe for true success is to find the best compromise between the greatest possible downforce and the lowest possible air resistance. There is no ideal set-up to suit every racetrack, so the true art of the designers is to get closer to the ideal than their competitors for every race. This is not an easy task, with 20 different possible settings for a rear wing and 100 possible settings for a front wing.

The aerodynamics are the most important factor in the design of a Formula 1 car. An air duct panel between the front wheel and the side panel, for instance, can add more speed than two or three extra horsepower. Only those teams with their own wind tunnel can keep up with the extremely fast development in this field. The engineers spend up to 15,000 hours every year at the wind tunnel, and each complex costs about 45 million euros.

Modern Formula 1 cars can withstand centrifugal forces of up to 4G without sliding off the track. The art of aerodynamics allows far higher cornering speeds than would be possible without downforce, and so not only ensures a better performance but also even more safety. As a rule of thumb, 35% of the total downforce is generated by the rear wing. However, as it also causes the greatest air resistance, it is the rear wing’s setting that is changed most from race to race. For the Italian Grand Prix on the high-speed track in Monza with its long straights and fast corners, the teams use flat wings to gain the highest possible speeds. On city tracks like Monaco, or circuits with lots of narrow corners, wing elements with a steep setting help generate as much downforce as possible so the cars can drive through the corners faster. The front wings are responsible for 25% of the downforce – a value which can quickly be reduced to just 10% by air turbulence if the car is travelling directly behind another car. The remaining 40% of the downforce is provided by the diffuser on the vehicle underbody, a type of air accelerator whose tunnels and ducts lead the flowing air towards the rear so that it generates the strongest possible suction effect.

In contrast to Formula 1, passenger cars tend to create lift at medium and relatively high speeds, because of their shape. As this relieves the load on the axle and reduces the driving stability – and therefore also the safety – developers aim to keep the lift as low as possible by creating minimal air resistance. “This takes a lot of detailed work in the millimetre range. It ranges from smoothing down the underbody to optimising the airflow through the wheels and even to working on integrated rear spoilers,” explains Dr. Christoph Lauterwasser from the Allianz Center for Technology. “That is the only way to achieve drag co-efficient values under 0.30 while at the same time minimising the lift on the rear axle. However, anyone travelling with a roof box or a bike carrier will completely undermine all that meticulous development work.”

In Formula 1, too, aerodynamics will always remain one of the most important factors in spite of all the changes to the regulations. The developers are a long way from exhausting all the possible options, so in the future, losing a hundredth of a second will still be a real drag.

Allianz Safety Check: Autodromo Nazionale di Monza

- by Mark Webber, WilliamsF1 driver:

“Monza is the last real high-speed track in Formula 1. The wings are set flatter than on any other circuit. That means the car is very difficult to control when you are cornering or braking before a corner. Driving flat out 70% of the time doesn’t only push the engines to the limit: it’s a really hot race – in the truest sense of the word – for the brakes too. But because Formula 1 uses only state-of-the-art materials, the safety of the drivers and the spectators is guaranteed in spite of these extreme material loads.”

Thanks to Allianz

Comments:

Post a Comment