Wednesday, September 28, 2005

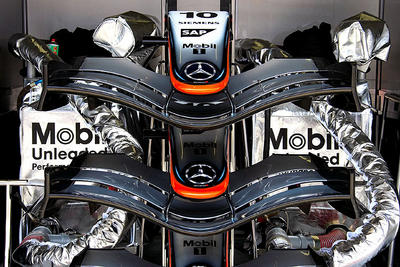

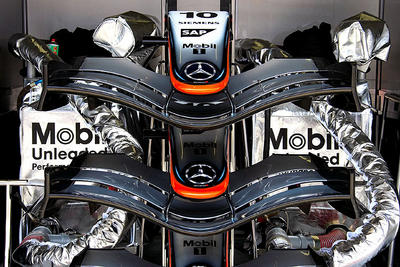

F1: A close look at the MP4-20’s nosebox

A beautiful and crucial structure

The nosebox has four key requirements

The nosebox has four key requirements

The nosebox is the first point of a Formula 1 car to puncture the air or, in the event of a head-on collision, to absorb a more solid impact.

This crucial structure has four key requirements: to channel air effectively for aerodynamics, to support the front wing, to be quick to change and most importantly, to protect the driver’s main safety cell - the monocoque - in a crash.

Made of carbon fibre impregnated with resin, the structure is laminated in order to provide the most effective energy-absorbing properties. During its construction, individual plies of carbon fibre are layered and staggered so that the car’s deceleration is controlled progressively.

"The beauty of composite construction is that you can put plies exactly where they need to be to optimise the load-bearing requirement," explains Matthew Jeffreys, Senior Project Engineer, McLaren Racing.

The component's function as the frontal energy-absorbing structure is regulated by Formula 1's governing body, the FIA, with its length being influenced by the amount of energy and deceleration it must sustain.

Each new nosebox design must pass two mandatory tests, one a static side load test and the other an impact test. In this, the nosebox is fitted to a monocoque - complete with driver dummy - mounted on a trolley and crashed into a wall. To pass the test, all the energy must be absorbed by the nosebox, with no damage incurred to the monocoque or dummy.

"People often comment that the test speed of 14 metres per second (around 50km/h) is not very fast compared with the speed at which a Formula 1 car travels," says Jeffreys. "But during the test the car is in effect hitting an immovable brick wall, whereas on the circuit the crash barriers take some of the energy so not all of it is absorbed by the nosebox itself." Upon impact, the carbon fibre will turn to dust.

"Generally the smaller the particles you are left with, the more efficient the structure has been," he explains. Another of the nosebox's crucial functions is as the supporting structure for the front wing assembly, which is mounted by two aerodynamically shaped wing hangers.

"A feature of the technical regulation changes for the 2005 season has been to raise the front wing," adds Jeffreys. "This has not really affected the structural requirement of the nosebox, but it has had an impact on the shape of the nosebox in order for it to fulfill the aerodynamic needs."

Since even the slightest contact may damage the front wing, another important feature of the nosebox is that it is quick and easy to change in a pit stop. The team has designed four quick-release fasteners which allow the unit to be detached from the car’s monocoque and replaced in a mere five seconds.

Team McLaren Mercedes takes seven noseboxes to each Grand Prix - two for each car, including the T-car plus a spare - and makes around 25 per year in total. As each new design must undergo a crash test, a revised design will only be introduced mid-season if there are significant aerodynamic advantages to be gained.

Tehnical specification MP4-20

Length: 780mm

Height: 394mm

Width: 300mm

Material: Pre-preg carbon fibre

Source McLaren Mercedes

The nosebox has four key requirements

The nosebox has four key requirementsThe nosebox is the first point of a Formula 1 car to puncture the air or, in the event of a head-on collision, to absorb a more solid impact.

This crucial structure has four key requirements: to channel air effectively for aerodynamics, to support the front wing, to be quick to change and most importantly, to protect the driver’s main safety cell - the monocoque - in a crash.

Made of carbon fibre impregnated with resin, the structure is laminated in order to provide the most effective energy-absorbing properties. During its construction, individual plies of carbon fibre are layered and staggered so that the car’s deceleration is controlled progressively.

"The beauty of composite construction is that you can put plies exactly where they need to be to optimise the load-bearing requirement," explains Matthew Jeffreys, Senior Project Engineer, McLaren Racing.

The component's function as the frontal energy-absorbing structure is regulated by Formula 1's governing body, the FIA, with its length being influenced by the amount of energy and deceleration it must sustain.

Each new nosebox design must pass two mandatory tests, one a static side load test and the other an impact test. In this, the nosebox is fitted to a monocoque - complete with driver dummy - mounted on a trolley and crashed into a wall. To pass the test, all the energy must be absorbed by the nosebox, with no damage incurred to the monocoque or dummy.

"People often comment that the test speed of 14 metres per second (around 50km/h) is not very fast compared with the speed at which a Formula 1 car travels," says Jeffreys. "But during the test the car is in effect hitting an immovable brick wall, whereas on the circuit the crash barriers take some of the energy so not all of it is absorbed by the nosebox itself." Upon impact, the carbon fibre will turn to dust.

"Generally the smaller the particles you are left with, the more efficient the structure has been," he explains. Another of the nosebox's crucial functions is as the supporting structure for the front wing assembly, which is mounted by two aerodynamically shaped wing hangers.

"A feature of the technical regulation changes for the 2005 season has been to raise the front wing," adds Jeffreys. "This has not really affected the structural requirement of the nosebox, but it has had an impact on the shape of the nosebox in order for it to fulfill the aerodynamic needs."

Since even the slightest contact may damage the front wing, another important feature of the nosebox is that it is quick and easy to change in a pit stop. The team has designed four quick-release fasteners which allow the unit to be detached from the car’s monocoque and replaced in a mere five seconds.

Team McLaren Mercedes takes seven noseboxes to each Grand Prix - two for each car, including the T-car plus a spare - and makes around 25 per year in total. As each new design must undergo a crash test, a revised design will only be introduced mid-season if there are significant aerodynamic advantages to be gained.

Tehnical specification MP4-20

Length: 780mm

Height: 394mm

Width: 300mm

Material: Pre-preg carbon fibre

Source McLaren Mercedes

Comments:

Post a Comment